- The following formula is used to calculate the CPK, or process capability index, of a given set of data. CPK = Min (USL – mean/3. std.), (mean-LSL/3.std.) Where CPK is the process capability index USL.

- Cpk Calculator is a free online tool that displays the process performance for the specified range. BYJU’S online Cpk calculator tool makes the calculation faster, and it calculates the performance of the.

- This can be done using the calculator above, or it can be done using a standard calculator or hand calculation. Finally, you need to analyze the results. PPM is used to bring a really small number into a more realistic number that you can visualize and analyze.

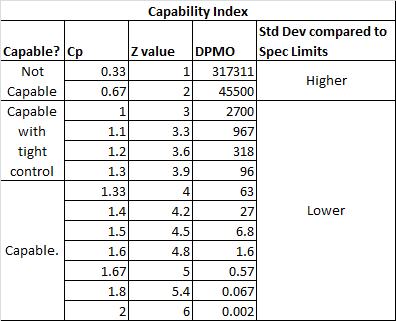

Cp stands for process capability and Cpk stands for process capability index. Both are used for the measure of a potential capability of a process in short term. The higher the sigma level, the better the process is performing. You can learn how to calculate Cp and Cpk values using this tutorial. Learn to calculate the Process Capability (Cp) and Process Capability Index (Cpk) values using the steps and few examples given here.

Learn to Calculate Process Capability Index - Tutorial, Definition and Example

Process Capability (Cp) Definition:

Process capability is a technique to find out the measurable property of a process to a specification. Generally, the final solution of the process capability is specified either in the form of calculations or histograms

Comment calculer le CP et CPK sur Excel ( une formule simple pour les gens qui ne se disposent pas du Minitab ) how to calculate CP and CPK with Excel.

Process Capability Index (Cpk) Definition:

Process capability index (cpk) is the measure of process capability. It shows how closely a process is able to produce the output to its overall specifications.

Formula :

Where,

USL = Upper Specification Limit, LSL = Lower Specification Limit.

Example :

Food served at a restaurant should be between 38°C and 49°C when it is delivered to the customer. The process used to keep the food at the correct temperature has a process standard deviation of 2°C and the mean value for these temperature is 40. What is the process capability of the process?

Given,

USL (Upper Specification Limit) =49°C LSL (Lower Specification Limit) =39°C Standard Deviation =2°C Mean = 40

To Find,

Process Capability & Process Capability Index

Solution:

| Process Capability : | |

|---|---|

| Process Capability | = (49 - 39) / (6 * 2) |

| = 10 / 12 | |

| = 0.833 | |

| Process Capability Index : | |

| Solution 1 | |

| (USL-mean/ 3*std.Dev) | = (49 - 40) / (3 * 2) |

| = 1.5 | |

| Solution 2 | |

| (mean-LSL/3*std.Dev) | = (40 - 39) / (3 * 2) |

| = 0.166 | |

| Now, find the minimum value. | |

| Process Capability Index | = min (Solution 1, Solution 2) |

| = min (1.5 , 0.166) | |

| = 0.166 | |

Cp and Cpk are used in Six Sigma Quality Methods for analyzing the performance of the process carried out to deliver any product.

Related Tutorials:

Top Calculators

Cpk Calculator Free Spreadsheet

Popular Calculators

Top Categories

There are two types of research in statistics such as quantitative and qualitative data analysis. Quantitative data which is used to the measure the values or counts and expressed in numbers and represented through name, symbol or number code. Qualitative data analysis are said to be categorical measurement which are not expressed in terms of numbers, but expressed by means of natural language. This section consists of the list of all qualitative and quantitative data analysis calculators.

Statistics Related Topics:

The frequency of observation can be calculated in quantitative data. Qualitative data are extremely varied in nature and captures the values which are not natural in numbers. Qualitative data's are not used mostly with inferential statistics because as all the techniques are based on the numerical values.